Please enjoy the website from a desktop for now.

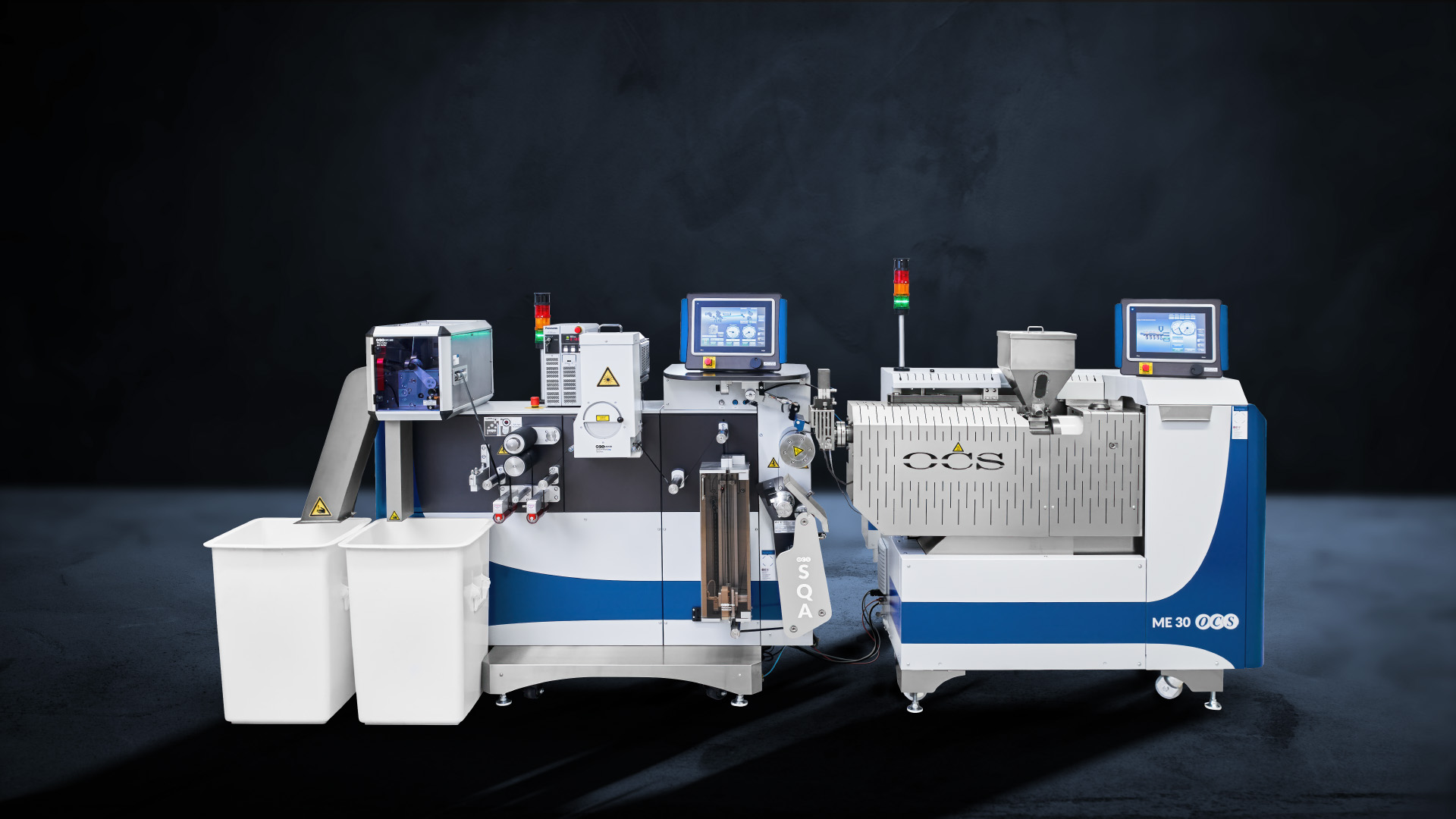

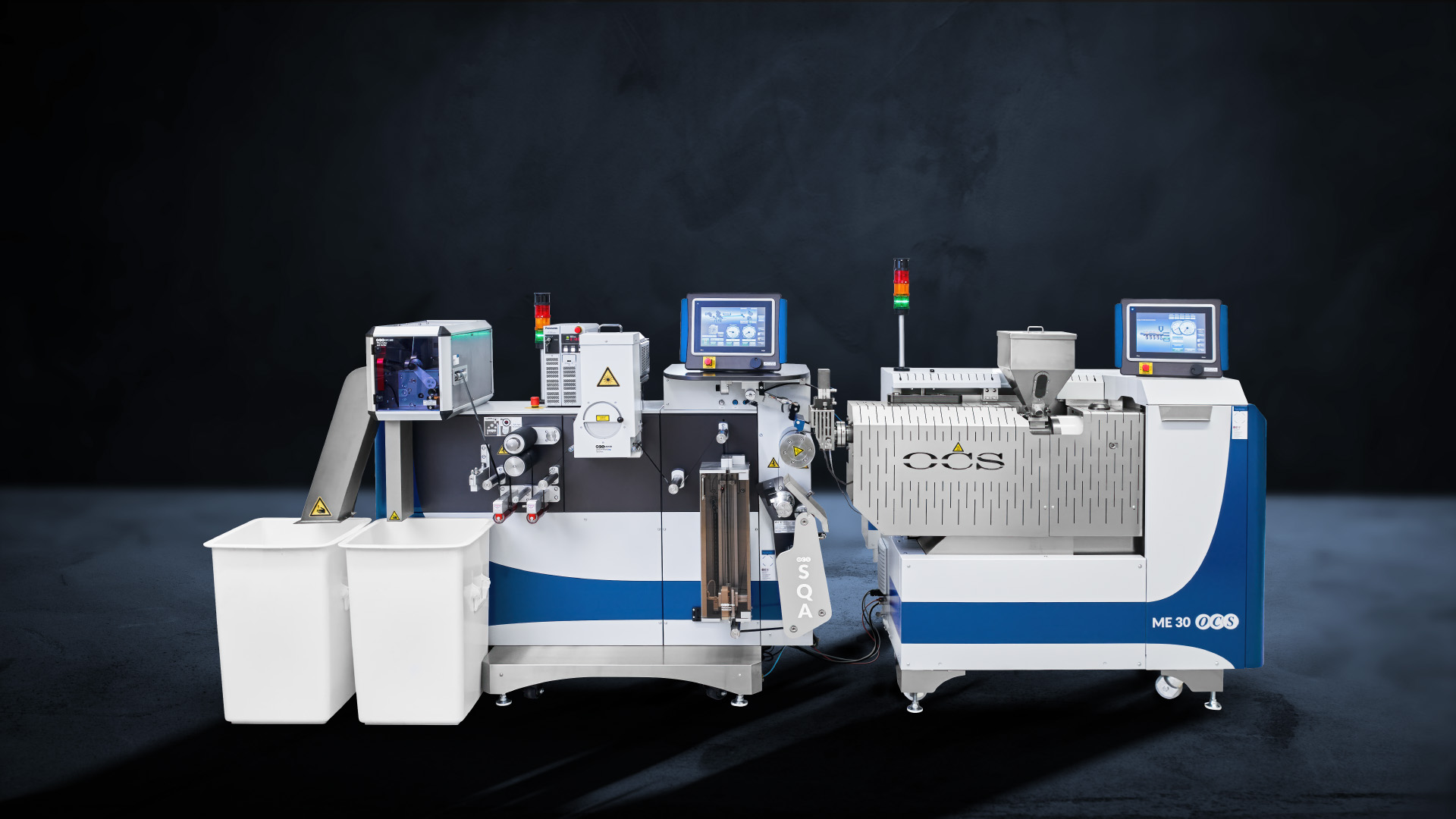

The OCS Tape Line type SSA® is used specifically to detect surface irregularities (pips ) on non-transparent polymer films (tape) in the wire and cable industry. The SSA® Line consists of a Measuring Extruder (ME) and a Modular Film Analyser with a Chill Roll (MFA-CR). During the measurement of the surfaces, the extruded polymer film (tape) passes over a chill roll, which leads the tape to the Surface Quality Analyser (SQA).

This high-resolution CMOS camera system uses a specially developed measuring roll to measure the height of the surface defects (so-called pips or agglomerates) with a resolution of 1 µm. In addition, the base diameter and the diameter at half the height of the surface defects are measured with a resolution of 10 µm. The analysis software provided allows the user to define height and diameter classes and to classify the measured pips based on these definitions.

The pips can then be marked with the LASER Marking System (LM100) or the Label Printer (LP100). The polymer film is then cut into strips using the OCS Film Cutter and Sorter (OFC100) and sorted into containers. The entire system can be easily managed via the control unit with software-based touch panel, for example to set device parameters, film tension and speed.